Stop settling for "good enough."

Are you battling inconsistent welds, constant rework, or compliance headaches in your pressure vessel fabrication? We understand. From intricate multi-pass welds and stringent code compliance to the critical need for optimal surface preparation and the battle against slag and contamination – every step in the path to flawless fabrication presents unique challenges.

At Weiler, we don't just sell abrasives; we deliver meticulously engineered solutions and expert guidance forged from decades of understanding pressure vessel manufacturing. Partner with us to confidently navigate complexities, achieve unparalleled quality, boost efficiency, and enhance safety in every weld. We're committed to helping you reduce rework, improve consistency, and directly impact your bottom line.

Tips for Overcoming Common Mistakes

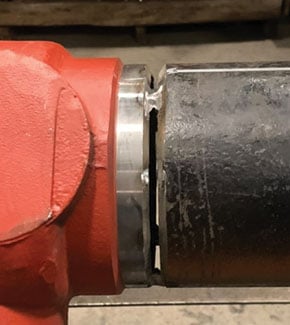

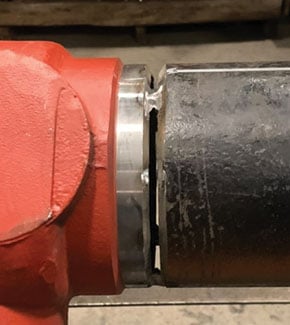

Precision Fit-Up

Precision Fit-Up

Accurate joint prep and alignment are essential for strong, consistent welds and fewer defects.

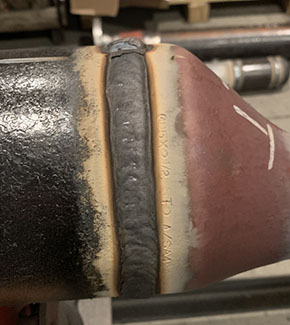

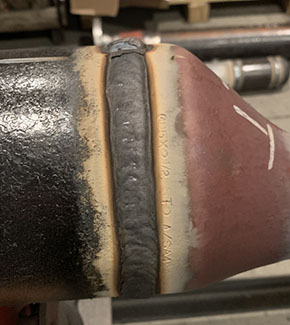

Root Pass Mastery

Root Pass Mastery

Grind and inspect the root pass for a solid base, improving subsequent layers.

Interpass Cleaning

Interpass Cleaning

Remove slag between passes to prevent defects and boost overall weld quality.

Code Compliance

Code Compliance

Stick to prescribed parameters to avoid defects like a lack of fusion.

Material Purity

Material Purity

Keep materials separate to avoid cross-contamination and corrosion.

Precision Fit-Up

Precision Fit-Up

Accurate joint prep and alignment are essential for strong, consistent welds and fewer defects.

Root Pass Mastery

Root Pass Mastery

Grind and inspect the root pass for a solid base, improving subsequent layers.

Interpass Cleaning

Interpass Cleaning

Remove slag between passes to prevent defects and boost overall weld quality.

Code Compliance

Code Compliance

Stick to prescribed parameters to avoid defects like a lack of fusion.

Material Purity

Material Purity

Keep materials separate to avoid cross-contamination and corrosion.The Right Abrasives for Pressure Vessel Excellence

Grinding or Notching Wheels: These are essential for precise root pass grinding, beveling, and heavy material removal. Our wheels are engineered for aggressive material removal while maintaining control, minimizing heat, and ensuring a clean surface for subsequent passes.

Resin Fiber Discs: Ideal for efficient weld blending, stock removal, and surface preparation. RFDs offer excellent versatility, conforming to contours for a smooth finish and preparing surfaces for optimal coating adhesion.

Flap Discs: Perfect for finishing, blending welds, and light stock removal. Flap discs provide a consistent finish, reduce vibration, and are excellent for reaching tight areas, contributing to a superior aesthetic and functional outcome.

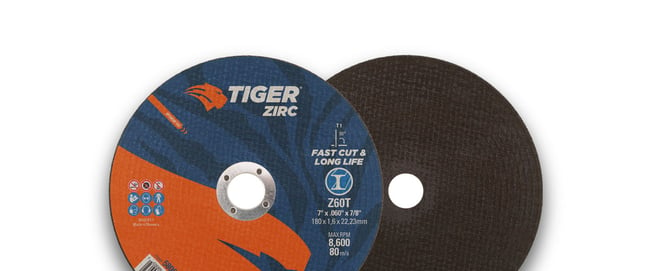

Cutting Wheel: Designed for fast, precise cuts in various materials, including stainless steel and exotic alloys. Our cutting wheels minimize burr formation, reduce heat buildup, and provide clean cuts, critical for efficient material handling and fit-up.

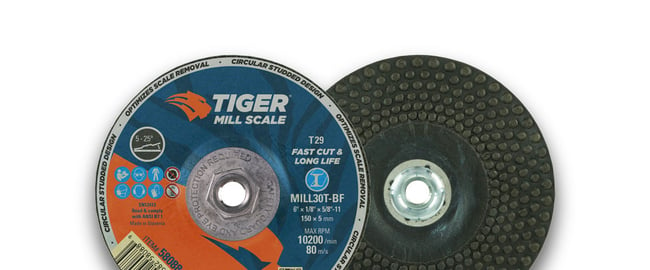

Mill Scale Discs: Specifically engineered to effectively remove tough mill scale, rust, and heavy coatings. These discs ensure a perfectly clean surface for welding, preventing defects and maximizing weld integrity and longevity.

Experience the Weiler Advantage: Cut Through Challenges

Cut Through Inefficiency

Cut Through Safety Issues